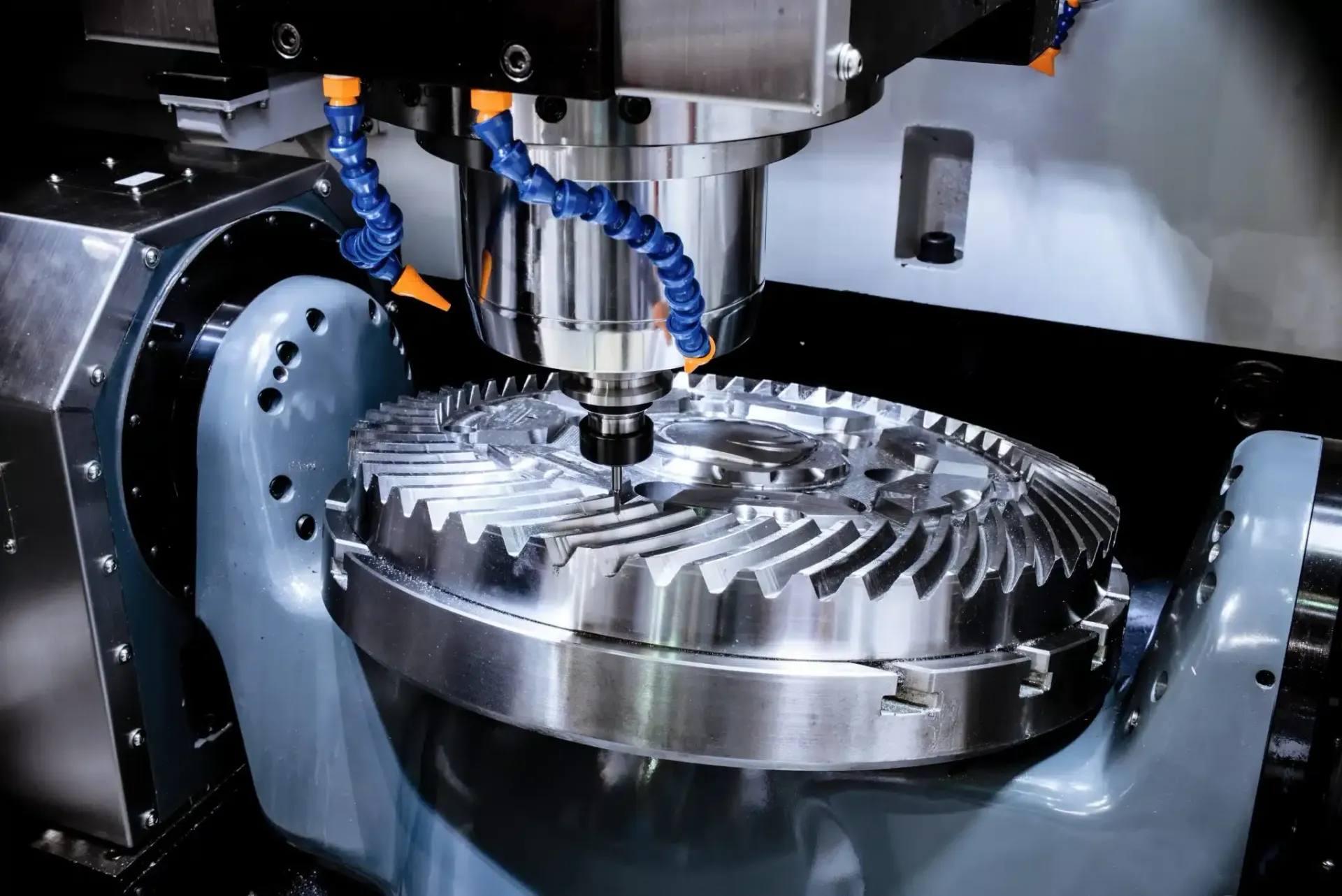

Precision Engineering

Our skilled team excels in product design, procurement, manufacturing, and finishing processes, ensuring high-quality and precise outcomes for every project.

Innovative engineering solutions for industry.

Gatenby Guaranteed

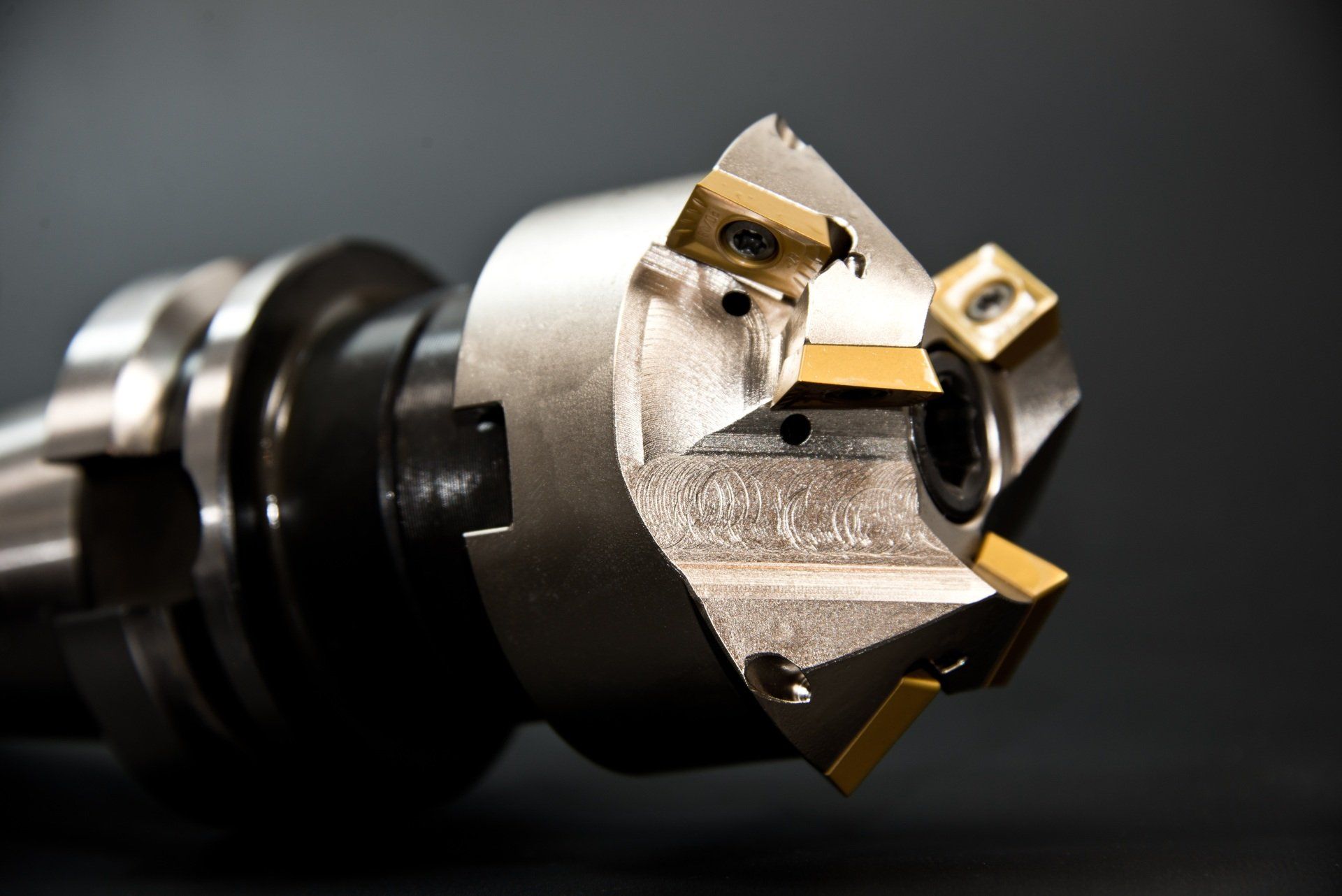

Gatenby Automatic Engineering provides cutting-edge engineering services for a variety of industries. Specialising in custom solutions, our services encompass product design, procurement, manufacturing, and finishing. With a focus on innovation and precision, we deliver high-quality CNC machining services tailored to meet the unique needs of our clients.

Our Services

Get in touch with Gatenby...

Contact us

About Gatenby

Gatenby Automatic Engineering Limited was founded in Christchurch in 1977 by Grant Gatenby.

The business started with the purchase of a traub (auto lathe) which was used to make rivets for the furniture industry. The business grew quickly and acquired an additional 6 traubs. In the early 80’s Grant went to Japan to purchase its first CNC lathe, a Mori Seiki SL2. This was followed by the purchase of an Okuma LC10.

To scale with growth the business moved a number of times to moving to its current premises located at 7 Watts Road. This facility was leased for several years before being purchased in 1993.

Sadly, Grant passed away in 1990 aged 44 years. That same year his son, Craig started working in the business aged 16 years. The company was managed by the factory manager, Bill Nordmeyer who helped scale the business with the purchase of two more CNCs, an Okuma MX45 machining centre and another Mori Seiki ZL15, a twin spindle twin turret lathe. Bill retired in 2011 after training Craig in all aspects of the business.

The business is now run by Craig Gatenby and continues to grow. In 2013 we purchased a Mori Seiki NLX2500 SY1700 which enables us to run 24/7/365, unmanned with an auto loading bar feeder. Since then, we have purchased 3 more in 2018, 2022 and 2023.

Gatenby Automatic services both local and international companies. While we service all industries, we have evolved as specialists in developing solutions for the brewing, automotive, power and electronics industries.